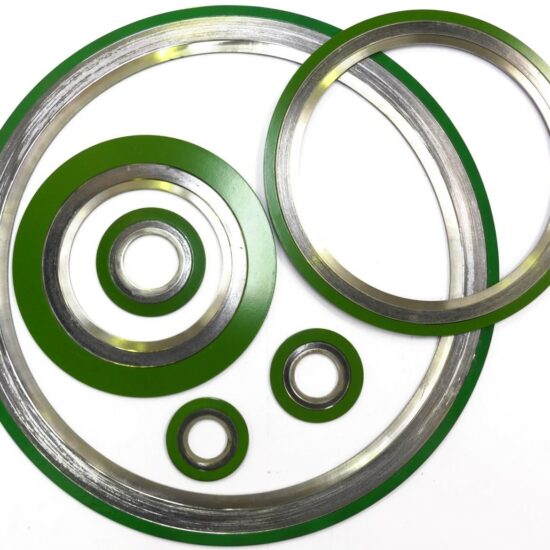

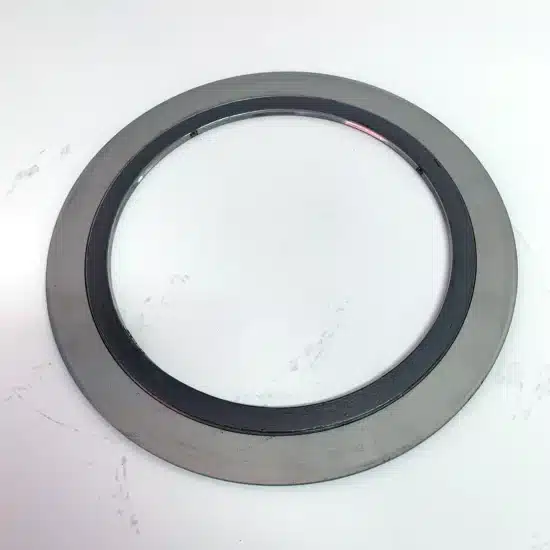

Spiral Wound Gaskets

Spiral wound gaskets have extremely strong sealing capacity and are used across many different industries.

Their versatility, and the fact that they have the ability to handle temperature and pressure fluctuations, mean that they can be adapted to suit most operating conditions and applications.

Spirals are ideal for very high pressure applications or in very corrosive or high temperature environments such as pipelines in the chemical and petroleum industries.

The gaskets can seal fluid pressures up to 250 bar and have a temperature range of between minus 200oC to 1000oC.

Spiral Wound gaskets are manufactured in three styles, and all manufactured to ASME B 16.20 Standard.

Standard Gaskets

Carbon or S/S outer ring only. This is the most common choice for RF and FF flanges.

Inner Ring Gaskets

As per Standard Gasket but with Inner ring also, usually S/S. This is a standard gasket with an additional inner ring fitted to provide an additional compression stop. This construction means that the sealing element is protected from heat and corrosion. Inner rings are standard on all gaskets NPS 24” class900#, NPS 12” and above in 1500# and NPS 4” and above in 2500#. All spiral wound gaskets with PTFE filler have inner rings fitted.

Style R Sealing Gaskets

These gaskets are sealing elements only, although they have several additional layers of winding strip for use in tongue and groove and male/

female flanges. They are also available in oval, round and diamond shape for valve bonnet and hand-hole applications, 3.2mm and 4.5 mm thick.

| SPIRAL WOUND GASKETS CODES | |

| GSWCO | CARBON STEEL OUTER RING ONLY |

| GSWSO | S/S OUTER RING ONLY |

| GSWCOSI0 | CARBON STEEL OUTER RING S/S INNER RING |

| GSWSOSI | S/S OUTER S/S INNER |

| GSWPN | PN |

| GSWPNSISO | PN S/S INNER S/S OUTER |

SPIRAL WOUND GASKETS SPECIFICATIONS

Temperature Limits for Common Materials

| Minimum | Maximum | ||||||

| Material | °F | °C | °F | °C | Abbreviation | Guide ring Colour Code |

|

| 304 Stainless Steel | -320 | -195 | 1400 | 760 | 304 | ||

| 316L Stainless Steel | -150 | -100 | 1400 | 760 | 316L | ||

| 317L Stainless Steel | 317L | ||||||

| 321 Stainless Steel | -320 | -195 | 1400 | 760 | 321 | ||

| 347 Stainless Steel | -320 | -195 | 1700 | 925 | 347 | ||

| Carbon Steel | -40 | -40 | 1000 | 540 | CRS | ||

| 20Cb-3 (Alloy 20) | -300 | -185 | 1400 | 760 | A-20 | ||

| HASTELLOY B 2 | -300 | -185 | 2000 | 1090 | HAST B | ||

| HASTELLOY C 276 | -300 | -185 | 2000 | 1090 | HAST C | ||

| INCOLOY 800 | -150 | -100 | 1600 | 870 | IN 800 | ||

| INCONEL 600 | -150 | -100 | 2000 | 1090 | INC 600 | ||

| INCONEL X750 | -150 | -100 | 2000 | 1090 | INX | ||

| MONEL 400 | -200 | -130 | 1500 | 820 | MON | ||

| NICKEL 200 | -320 | -195 | 1400 | 760 | NI | ||

| Titanium | -320 | -195 | 2000 | 1090 | TI | ||

Temperature Limits for Filler Material

| Minimum | Maximum | |||||

| Material | °F | °C | °F | °C | Abbreviation | Stripe Colour Code |

| Ceramic | -350 | -212 | 2000 | 1090 | CER | |

| Flexible Graphite | -350 | -212 | 950 | 510 | F G | |

| PTFE | -400 | -240 | 500 | 260 | PTFE | |

| Verdicarb (Mica Graphite) | -350 | -212 | 550 | 288 | VC | |