Gasket Materials

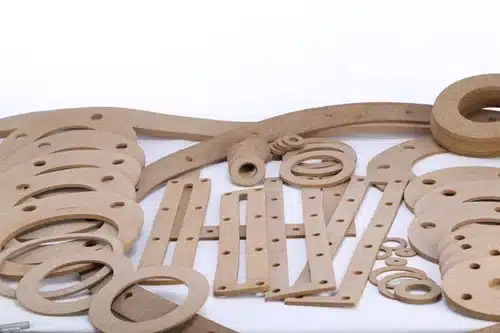

Shuk Engineering Distributors have the capability to produce or supply a full range of standard soft cut, metallic and semi-metallic gaskets.

A rubber gasket is a type of mechanical seal that is used to prevent leaks between distinct substrate sections. As an expert gasket supplier, rubber and shims are one of our core products, as we stock all sheet materials and have the facility to manufacture custom parts as well as standard patterns, such as ANSI/ASME and the European DIN pipe flanges.

Silicone rubber gaskets are high-performance mechanical seals with an exceptional resistance to extreme temperatures. Silicone are used to prevent leaks between different substrate sections in a wide range of applications.

The core difference between asbestos and non-asbestos gaskets is that the former contains asbestos, which is used as a reinforcing fibre whilst non-asbestos gaskets do not. Due to its role as a reinforcing fibre, asbestos is known to be strong and is known for its high resistance to chemicals and heat. Although such properties make asbestos an excellent gasket fibre, they also make it a harmful substance to work with. It is for this reason that the majority of gasket manufacturers now offer non-asbestos reinforcing fibres in the production of gaskets that are equal to or better than asbestos gaskets used to be produced. One type of fibre that is commonly used is aramid fibre (Kevlar) and is known for being around 2 to 9 times more durable than asbestos.

The main function of an EPDM rubber gasket is to fill the space between two or more surfaces in order to adequately prevent any seepage from or into objects. EPDM rubber gaskets are also used to fill irregularities or gaps between machine parts in order to increase the lifespan of machinery. EPDM gaskets are well-known for their excellent weathering resistance. Coupled with outstanding UV and ozone resistance properties and the ability to withstand high temperatures, EPDM (Ethylene Propylene Diene Monomer) has excellent weathering properties and is therefore ideal for use outdoors, where it will be exposed to the elements.

An insertion rubber gasket is made from a natural / SBR commercial compound with a single-ply cloth encapsulated to reinforce the sheet. This provides improved tensile strength and helps prevent the extrusion of the rubber insertion gasket. Sometimes referred to as cloth-inserted rubber gaskets, these gaskets are suitable for general-purpose use where there will be no fuel exposure.

This inorganic fibre gasket material is designed to offer excellent thermal stability with minimal weight loss, resulting in reduced creep relaxation. The material used for this IFG gasket is manufactured using inorganic fibres and a nitrile rubber binder.

When a traditional seal cannot provide a good solution, bonding rubber to PTFE can be considered a more viable option. As your custom rubber gasket expert, we can support you with designing and developing PTFE rubber gaskets that meet your specific requirements.

We offer a comprehensive range of quality recognised brands of materials, including Non-Asbestos Fibre, Asbestos Fibre, flexible graphite, Inorganic fibre, modified PTFE styles, which can be cut to any shape or size. Our most common range is Raised Face and Full Face Gaskets to ASME standards.

We keep an extensive range of sheet material in stock, and this means we can manufacture gaskets for a wide range of clients in many industries, and to a wide range of specifications and tolerances. In addition, we can precision cut non-standard gaskets using our highly sophisticated and technically advanced cutting machines.