Lamons provides the full array of Isolation gaskets including: 1/8” retainers with pressure energized seals (IsoGuard), steel core with spring energized seals (Defender) and API 6FB firesafe isolation (Defender-FS).The ISOTEK™ sealing and isolation product line is manufactured out of the Lamons Denver facility. This is a dedicated 17,000 sq. ft. facility, completely designed for the ISOTEK products. All products are manufactured in the U.S.A to ISO 9001:2015 standards. Real time production boards are utilized throughout the entire manufacturing process. A paperless production floor allows for streamlined production and assures quality and accurate dimensions which are critical for sealing performance.

Our engineered flag ship products are the ISOGUARD™, DEFENDER™, DEFENDER™ FS and KI (Kammpro Isolation). These gaskets service the Energy and Water markets and cover a wide range of applications (Standard, Critical, Fire-Safe, Hi-Temp and NSF-61). For economical solutions, flat gasket technology is available.

ISOGUARD™ Sealing/Isolation Gaskets

The ISOGUARD™ sealing/isolating gasket system is designed for general applications where electrical flange isolation and corrosion control are required on pipes containing water/wastewater, gas, natural gas, oil and other hydrocarbon based medias up to 302ºF (150ºC). Available for flat face, raised face and ring type joint flanges. The ISOGUARD sealing/isolating gasket system consists of a retainer with an incline-plane seal groove designed to optimize each seal’s elastic memory, in conjunction with a proven rectangular sealing element (“Quad” ring). This design guarantees low bolt load requirements and high sealing reliability.

| Gasket Type | Retainers | Seal Elements | Pressure Class |

| E and F | G10, G11, G7, Phenolic | PTFE, Nitrile, Viton, EPDM | ANSI(150#-1500#, API (2-5K), PN (20-250) |

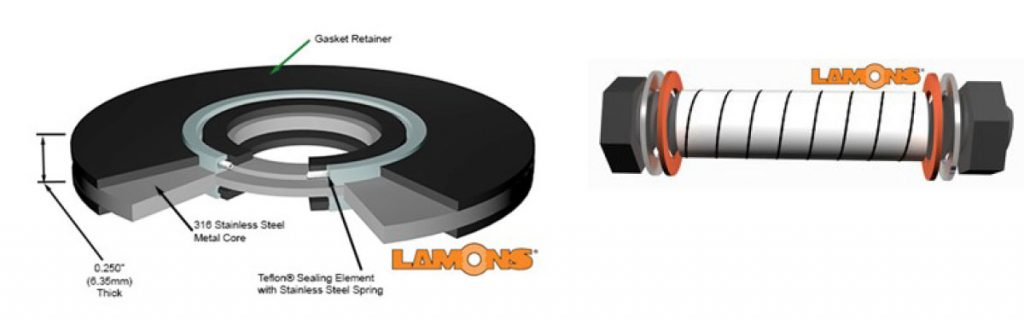

DEFENDER™ Sealing/Isolation Gaskets

The DEFENDER™ sealing/isolating gasket system is designed for critical/extreme applications. Manufactured with a 316 stainless steel core retainer and laminated on both sides with high strength laminates, the DEFENDER gasket is resistant to deforming under load and is used when electrical isolation and corrosion control are required on pipes containing gas, natural gas, oil and other hydrocarbon based medias up to 392ºF (200ºC). Available for flat face, raised face and ring type joint flanges from 1/2” to 60” (including corresponding API and DN diameters), ANSI 150-2500#, API 2-10K and PN20-PN420, the DEFENDER gasket is an engineered solution for trouble-free operation that eliminates costly leaks and provides a solution for fugitive emissions.

| Gasket Type | Retainers | Seal Elements | Pressure Class |

| E and F | G10-G11, S316 Core G10-G11, Duplex Cores G10-G11, Inconel Cores |

PTFE Spring-Energized, Viton, Nitrile | ANSI(150#-2500#), API (2-10K), PN (20-420) |

DEFENDER FS™ Sealing/Isolation Gaskets (Fire Safe)

The DEFENDER FS™ sealing/isolating gasket is designed to withstand the rigorous API standard 6FB (Third Edition) test and therefore provides a solution for those who want to electrically isolate their flange while also requiring protection against the introduction of fire in and around the flange. The objective of the test is to monitor the total leakage for the duration of the burn/cool-down cycle and during re-pressurization. Leakage was determined by the total water level drop through a visual sight gauge during the burn/cool-down cycles, by manually catching the water in a calibrated container during re-pressurization. The results concluded that the Defender FS Gasket was able to maintain its fire safe characteristics throughout the entirety of the test. During the 30 minute burn and 30 minute cool down period, the measured leakage was 0 ml/min versus the allowable rate of 22.765 ml/min. The leakage rate during the re-pressurization cycle was 5 ml/min versus the allowable rate of 22.765 ml/min. Based on years of technological experience, the DEFENDER FS sealing/isolating gasket not only meets but exceeds the pressure-containing capabilities in standard 6FB (Third Edition) as outlined by API.

| Gasket Type | Retainers | Seal Elements | Pressure Class |

| E and F | G10-G11, S316 Core G10-G11, Duplex Cores G10-G11, Inconel Cores |

KMT (Kammpro/Mica/PFTE) | ANSI(150#-2500#), API (2-10K), PN (20-420) |

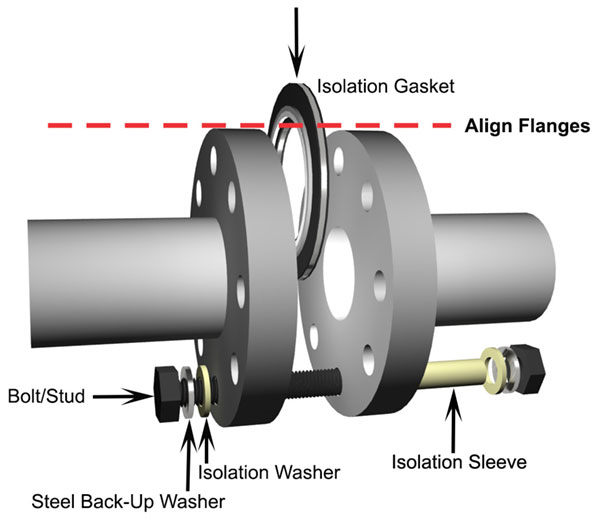

Sleeve and Washer Sets

Sleeve Material Offered: G10, G11, Nomex, Mylar, Mica

Washer Material Offered: G10, G11, Phenolic, Mica, HC, Steel ZP, 304SS, 316SS

Single Washer Set (per bolt/stud)

- (1) ea. 1/8” {0.125”} (3.18mm) thick Steel ZP Washers

- (1) ea. 1/8” {0.125”} (3.18mm) thick Isolating Washer

- (1) ea. Isolating Sleeve

Double Washer Set (per bolt/stud)

- (2) ea. 1/8” {0.125”} (3.18mm) thick Steel ZP Washers

- (2) ea. 1/8” {0.125”} (3.18mm) thick Isolating Washers

- (1) ea. Isolating Sleeve

The most commonly used and specified Sleeve and Washer Set Combinations

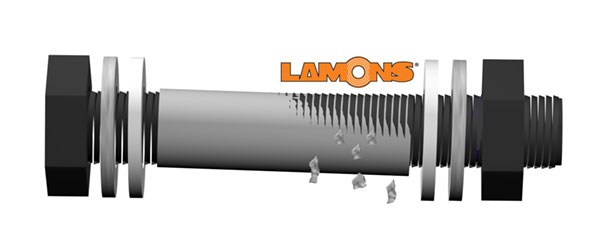

Cut-Through Resistance

Cut Through Resistance and Flexural Strength is critical in selecting sleeve material for your flange isolation kit application. As nominal pipe size increases, as well as ANSI or API class, the fasteners (bolts/studs) increase in size and torque is generally higher. Larger and heavier stud bolts with higher torque loads can more easily cut through material during installation. This is more likely to occur if flanges and bolt holes are not in perfect alignment. Use or specify G10 sleeve material as a standard for all applications. Or consider G10 sleeves for applications of Nominal Pipe Size 12” and larger and ANSI pressure class 600# and higher.